Building Campaign Navigation

Investing in the Future

View our entire construction photo gallery to follow the ECE ILLINOIS Building progress.

View our entire construction photo gallery to follow the ECE ILLINOIS Building progress.

Recent Posts:

- ECE Building includes state-of-the-art music lab

- Donor wall celebrates leadership donors to the Building Campaign for ECE ILLINOIS

- Robotics Laboratory prepares students for the future

- A revamped Digital Signals Lab

- ECE Building grounds’ history with Illinois

- Generating improved power labs

- Low donation funds classroom wing

- Introducing the Open Projects Lab

- $1 million gift makes Srivastava Senior Design Lab possible

THE BUILDING CAMPAIGN FOR ECE ILLINOIS

ECE ILLINOIS dedicates two sculptures at new building

As students enter the new Electrical and Computer Engineering Building, they are welcomed by two sculptures symbolizing the influence ECE ILLINOIS has had on the world.

The two sculptures, “Amplifiers” and “Diss-Connections,” were unveiled to the public Oct. 10, 2014, as a part of the Electrical and Computer Engineering Building’s dedication ceremonies that day. Professor George Gross, chairman of the Illinois Art-In-Architecture committee that commissioned the work, introduced the sculptors during two short art dedication ceremonies.

The Capital Development Board administrates the Art-in-Architecture Program to promote and preserve the arts by commissioning works of art for public buildings. The ECE Building project cost $95 million, and the State of Illinois paid for half of it. Private and corporate donations paid for the other half.

At the east entrance of the building stand two structures that make up the “Amplifiers” piece by Nicole Beck. The sculpture is a representation the work of two ECE ILLINOIS legends, John Bardeen and Nick Holonyak Jr. The piece representing Bardeen is on the north, and Holonyak, the south.

In preparation for the construction of the sculpture, Beck spent time studying Holonyak’s discovery of the first visible LED. It became her inspiration for the sculpture’s oscillating pole design.

“This piece is about the collaboration between professor and student, and then finally fellow professors,” Beck said of her sculpture design at the ceremony. “This is the symbol of the oscillating poles that come out of an LED. These are the exact shapes that are emitted.”

ECE ILLINOIS senior Brady Salz talks about his work on the LEDs in “Amplifiers” during the the piece’s dedication ceremony as sculptor Nicole Beck looks on.

Beck expressed gratitude to ECE ILLINOIS senior Brady Salz, who assisted with the LED lighting on the oscillating panels of the sculpture. Salz said that since coming to ECE ILLINOIS, working with lights is something he has always wanted to do.

“In high school, I was good at math and science, but I didn’t know what I wanted to do,” Salz said. “I went on YouTube and looked up what engineers do. It turns out electrical engineers get to play with LEDs. They get to make things light up. Three years later, I get to make bigger and better things light up.”

At the ECE Building’s Wright Street entrance, John Adduci’s “Diss-Connections” reminds students of one of the most fundamental elements of engineering: wire. He came up with the design for the ECE building’s west entrance while touring Everitt Lab and seeing wire everywhere he looked.

Sculptor John Adduci talks about “Diss-Connections” at the piece’s dedication ceremony Oct. 10, 2014. Professor George Gross looks on.

Adduci said the design is supposed to be simple and symbolic of the connections engineers make in their work.

“Everything is relative to connecting something to something else,” Adduci said. “That’s how we all get together. That’s even how we have students connect when they are together on campus. It creates a connection. That was the whole idea behind the piece.”

In his introduction, Gross praised Adduci for the fluidity of his metal work on the sculpture, and said it’s a welcome piece for a heavily used entrance of the new building.

“It provides an evocative and whimsical statement of the various widening aspect of the work students and faculty in the department perform,” Gross said. “We are very excited to see this work here, and we welcome its contributions to the overall aesthetics of this building and our campus.”

ECE Building includes state-of-the-art music lab

In the new ECE building, a specially designed lab space gives students an opportunity to develop as both engineers and musicians.

The new music lab, located in 3024 ECE Building, is more than double the size of the previous space in Everitt Lab.

Lippold Haken, an ECE lecturer, is excited that ECE 402, Electronic Music Synthesis, has two lab stations for students to work on instead of one. Now, the class is set up in a room that is acoustically isolated from the rest of the building. The upgrade creates an environment that is much more conducive to the music making process than what was previously available.

“In Everitt Lab, we had a small room that we had retrofitted with acoustic carpet on the wall, and we could only put one station in there,” Haken said.

Students now have the opportunity to schedule more convenient times in the lab. At Everitt, there was an issue of students having to schedule after midnight in order to secure lab time, but the new space has created much more availability for students.

Lab time is a crucial aspect of the class because it gives students the opportunity to actually work with the sound equipment. All of the equipment found in the lab stations is also used in the movie and gaming industries.

“Sound design can mean a lot of different things,” Haken said. “In a lot of cases, the sound designer is a person who selects the best sounding recording and mixes it in. It can also mean something much more extreme like when a sound designer creates new sound algorithms.”

The devices in the music lab are meant to challenge students. Haken hopes students walk away from the class with greater understanding that engineering isn’t always about finding ways to make things easy. Creating music with a synthesizer should be a challenging process that requires a lot of time and effort, just like creating music with an acoustic instrument.

“Engineers have worked really hard to make musicians’ jobs easier,” Haken said. “This has worked to an extent, but it’s also had the negative effect of deskilling people. It has made it almost so easy that you can replace the musicians with a synthesizer. At that point, you also lose something. You have to be pretty hard of hearing to not be able to tell the difference between an orchestra and synthesizer.”

Since joining the class, junior Molly Pace has enjoyed the opportunity to explore her musical interests, and said that the lab time has really helped her solidify its concepts. She decided to take the class after she saw Haken do a demonstration in ECE 110 of one of the most innovative items in the music lab: the Continuum Fingerboard.

Haken invented the Continuum Fingerboard and said that many students are attracted to the class because of the opportunity to work with the instrument. While students won’t have enough time to master the instrument, they will get a chance to experiment with it.

ECE 402 currently has about 60 students each semester, which makes it one of the largest technical classes of its type in the world. However, Haken would like to build a larger culture around the new music lab and develop students toward becoming even more passionate about the music they create.

“I want to attract even more students who will spend time with the art,” Haken said. “It’s hard for students to have free time, but to actually pursue art is something that I think is very important in modern society.”

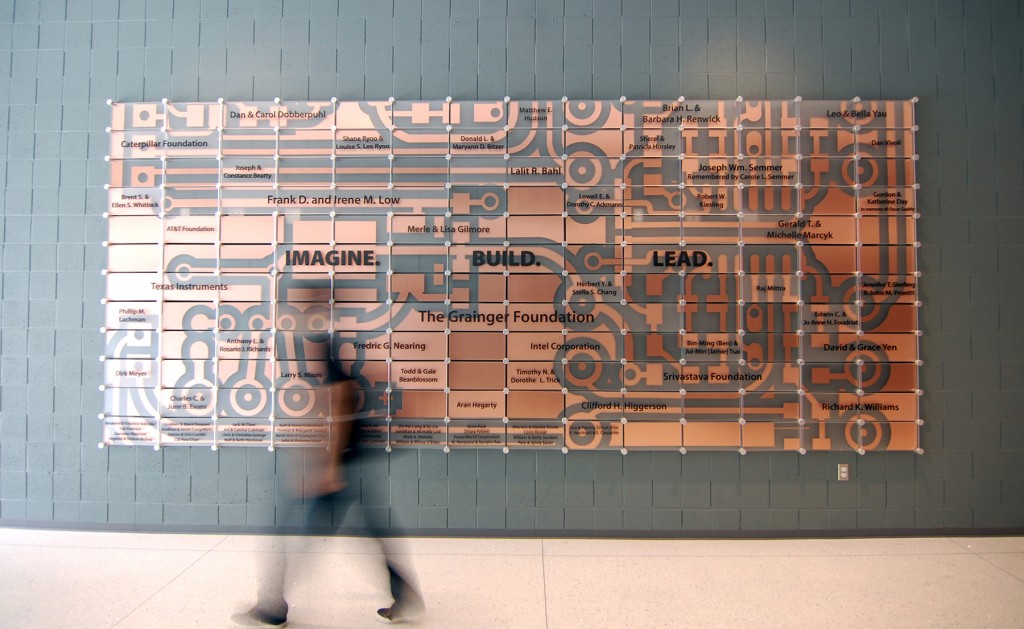

Donor wall celebrates leadership donors to the Building Campaign for ECE ILLINOIS

In some ways, completing the new ECE Building and populating a circuit board are rather alike. Both require the right components in the proper orientation. For the circuit board, these components include microprocessors, capacitors, micromachined sensors, and the like. For the new ECE building, they include the people who joined the department in the building campaign, offering financial support.

To recognize those donors in perpetuity, an art installation has been mounted between the lobby and the first-floor lecture halls. It resembles a wall-sized circuit board, measuring more than 18 feet long and 8 feet tall. The center features the motto, “Imagine. Built. Lead,” thoughts that have echoed through the building campaign. Around it are the names of major supporters.

“The reason we used the circuit-board design is, we thought of the donors as components,” said J. Todd Hearn, the university graphic designer who, along with Brandon Christie at Dean’s Graphics, conceptualized the donor wall. “When we came up with the circuit board, it was just, ‘Ah ha!’”

The wall has been designed in two layers. The background is the enlarged circuit board, with copper film on rectangular tiles of acrylic glass. The outer layer, elevated on aluminum standoffs, uses congruent rectangles, also in clear acrylic, which offer a clear view of the circuit pattern beneath. Interspersed within these are frosted rectangles with the names of the donors written in raised bronze lettering.

“Alumni and friends have played an essential role in ensuring that the new ECE Building is a state-of-the-art reality,” said Steven George, the senior director of advancement at ECE ILLINOIS. “We couldn’t have accomplished such an ambitious project—complete with net-zero energy features—without their support.”

The cost for the building, including furnishings and lab equipment, amounts to $95 million. Half of the funding came from the State of Illinois, while the other half has come from individual and corporate supporters. Already, the building is proving to be an academic and social hub for students, with new features ranging from a host of instructional labs lab to ample collaboration spaces.

The copper on the wall was fabricated using a die-cutter, which punches out the pieces using a custom-made blade, rather like an automated, super-sized cookie cutter. The pattern is based on a section of an actual circuit board designed by Skot Wiedmann, an instrument and measurement technician in ECE’s Electronics Services Shop. He used the board in an audio processing unit for electronic music, which he designed as a graduate student.

“I do try to approach these designs as both and artist and an engineer, so the aesthetics are important to me,” Weidmann said. “I actually still use [the processing unit] occasionally.”

According to Hearn, this donor recognition design may be the first of its kind. Neither he nor Christie had seen a wall-sized circuit board like this, and they were particularly pleased with the idea of using copper in the design. Not only is the building a vanguard accomplishment, but even this donor recognition wall is an innovation.

“Illinois always likes to be the first,” Hearn said.

It’s not too late to donate to the Building Campaign for ECE ILLINOIS. For more information, please contact Steve George at steveg@illinois.edu or (217) 244-8023.